Basic knowledge of steel structure - connection of steel structure

Pubdate:

2024-09-19

Structural Steel Fundamentals

Structural Steel Fundamentals

Connection of steel structures

一、 Basic requirements of steel structure connection

1. Direct path of force transmission

2. Sufficient node bearing capacity

3. Appropriate node stiffness

4. Simple node construction, easy installation and maintenance

二、 The basic way of steel structure connection

1. Weld connection

2. Bolt connection

3. Rivet connection

01

Weld connections

Welded joint is a manufacturing process that joins metals by means of heat, high temperature or high pressure. It is very much used in steel buildings and is the most basic and widely used connection method for modern steel structures.

Advantages

- Simple construction - members of any shape can be directly connected without the need for auxiliary parts

- Save labor and materials - easy processing, no drilling and weakening of the cross-section

- Quick construction - can be Fast construction

- Automated operation - good tightness of connection, high stiffness, good integrity

Disadvantages

- The material is easy to become brittle

- Produces residual stress, residual deformation, welding defects

- Adversely affects the fatigue and stability of the steel structure

- Depends more on the skill level of the welder

- Higher inspection workload in case of higher quality inspection requirements.

02

Bolted connection

A bolted joint is a fastener such as a bolt that connects the connecting parts into a single unit. There are two types of bolted connections: normal bolted connections and high-strength bolted connections.

Advantages

- Simple construction, easy to install and dismantle, high requirements for installers

- Friction type high-strength bolts with good power performance

- Fatigue resistance, easy to prevent crack expansion

Disadvantages

-Costly material, weakened cross-section of the hole

-High accuracy of bolt hole machining

- Higher inspection workload in case of higher quality inspection requirements.

03

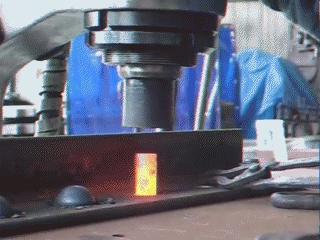

Rivet connection

Rivet connection is a rivet with a semi-circular prefabricated head at one end, the nail shank will be burned red and quickly inserted into the nail hole of the connecting part, and then the other end will be riveted into the nail head with a rivet gun as well, so as to make the connection to achieve tightness.

Rarely used in load-bearing structural steel connections today.

Advantages

Good plasticity and toughness, good resistance to dynamics

Disadvantages

Material-intensive, heating and riveting process is extremely labor-intensive.

Tell me to share more steel structure knowledge with you!

Related News

Quick overview of container knowledge

2024-10-06